When it comes to print, coatings do more than just add a finishing touch, they enhance durability, elevate the visual impact, and create a memorable experience. From protecting against wear and tear to adding tactile effects, coatings help your printed materials stand out.

Why Use Coatings?

Coatings provide a protective layer on the printed surface, enhancing both appearance and functionality. Beyond protection, coatings add an aesthetic element, offering various finishes that can completely transform the look and feel of a project.

Types of Coatings

Gloss Coating – A high-shine, reflective finish that enhances colors.

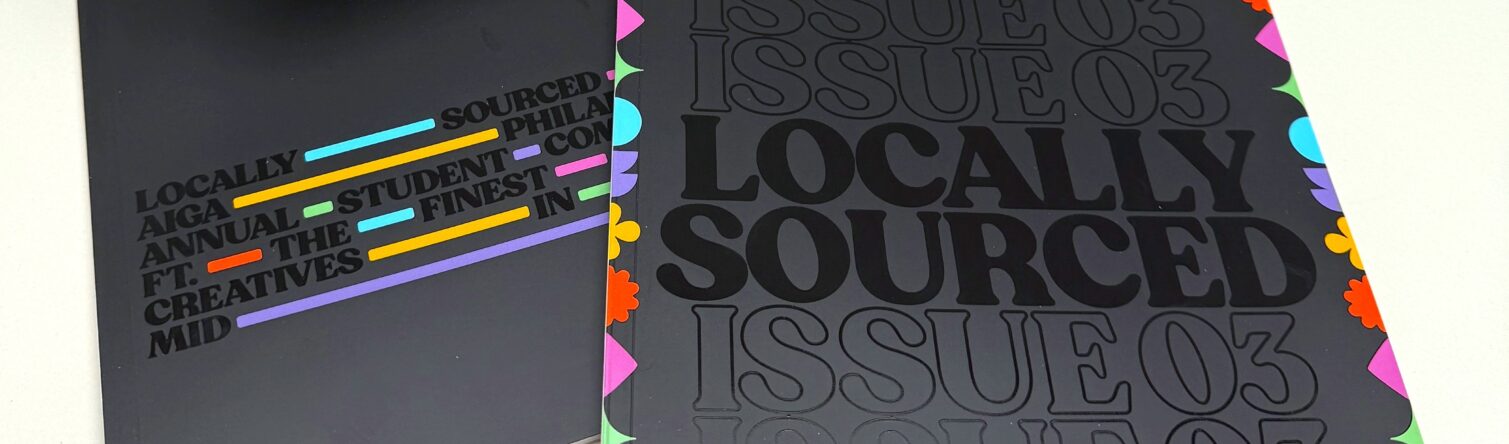

Matte Coating – A smooth, non-reflective finish.

Aqueous Coating (AQ)- A water-based conventional coating that provides protection to help prevent smudging and minor damage.

UV Coating – A durable coating cured with ultraviolet light. Not every printer has this capability, but at Allied we do.

Raised UV Coating – A dimensional effect that adds a luxury feel. This coating can be adjusted to different heights for a customized effect.

Spot Varnish – A selective coating applied to specific areas of a design to highlight details, creating contrast and visual interest. This coating is applied on a press with a printing plate.

Soft Touch Coating – Creates a velvety, luxurious feel that enhances the tactile experience of your printed piece.

Textured Grit Coating – Applied on UV presses, this coating adds a gritty texture with a sandpaper-like feel for a unique, high-impact finish.

The Allied Advantage

At Allied, we help clients navigate the print world to achieve optimum results. Understanding your intent for choosing to use a coating on a project is essential. Our team works closely with you, offering insights and recommendations to ensure you choose the right coating for your project. Our expertise enables us to guide you through every step to avoid costly mistakes and maximize your print’s impact.

Innovative Coating Capabilities at Allied

- Triple Coating Units: We can apply multiple coatings in a single pass, reducing turnaround times and increasing cost efficiency.

- Film Lamination: An additional process that enhances durability and avoids cracking, ideal for projects that require extra durability.

At Allied, we don’t just print, we partner with our clients to bring their vision to life. Whether you need a striking annual report, a tactile alumni magazine, or a high impact viewbook, our team is here to ensure your print pieces stand out. Contact us today!